In collaboration with Kalypso and IEEE, the 3D Retail Coalition (3DRC) hosted the sixth annual Grand Challenge in late 2023. Teams from around the world submitted projects focused on this year’s theme: the transformative potential of Generative AI for 3D Product Creation. With creative research and innovative solutions, teams aimed to show how their projects could revolutionize how retailers and brands discover, create, make, and sell new products.

Two outstanding winners were selected this year: teams from the University of British Columbia (in the academic category) and Apotheosis Group (in the start-up category). Here’s a look at their projects:

University of British Columbia: Goal-oriented 3D Pattern Adjustment with Machine Learning

Team Members: Megha Shastry, Ye Fan, and Dinesh K. Pai, Department of Computer Science

Garments with poor fit are a leading cause of waste in the fashion industry, with severe environmental impact.The critical task of adjusting a garment pattern to achieve good fit, such as removing pressure points, is currently done by human trial-and-error. Designers must iteratively adjust and estimate 2D pattern edits to achieve desired fit in 3D. This can be a frustrating and time-consuming process.

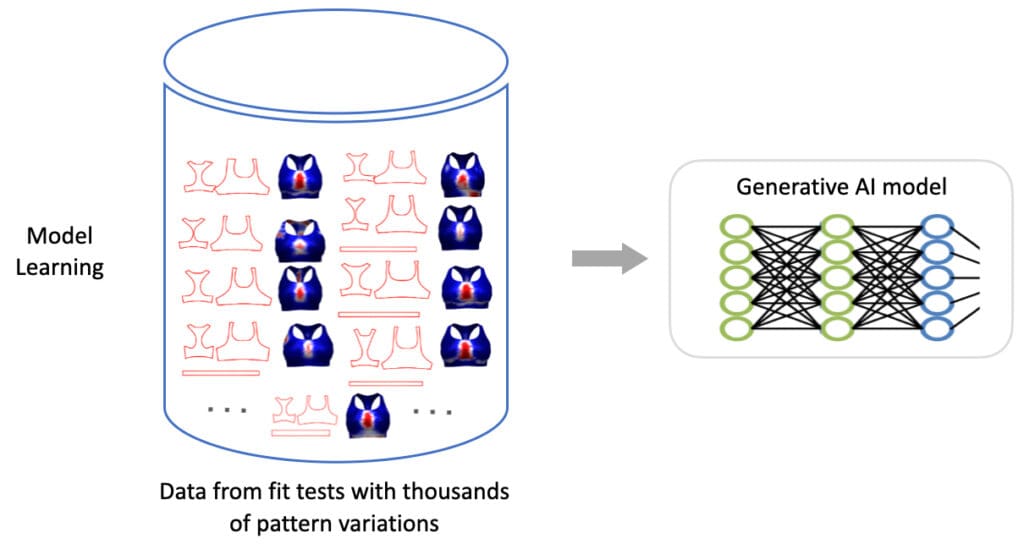

Fit can be quantified using physical fit attributes such as ease and pressure on the body, that can be computed by recent 3D virtual fit testing software (e.g., VitalFit, VStitcher, Clo3D, and Style 3D). We introduce a novel system, called uFit, to enable pattern makers to directly specify the changes they would like to see in a fit attribute (e.g., “reduce pressure here”) and infer the required pattern adjustments.

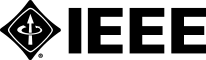

The system consists of an offline learning phase for training a generative model using a large amount of simulated fit data, and a real-time interaction phase for using the learned model to make fit adjustments.

For the learning phase, we first generated several variations of an initial pattern (e.g., a block). The dataset was generated by carefully incorporating meaningful pattern variations that modify how a garment fits. For a bra pattern, our dataset consists of changes to “sleeve depth”, “bust width”, “bust length”, etc. For a leggings pattern, our dataset consisted of patterns with varying “crotch depth”, “waist width”, “thigh width”, etc. Then we simulated the fit of each of the pattern variations in parallel using VitalFit software from Vital Mechanics. Pattern variations along with corresponding fit results are used to train the model. The trained model can predict changes in the pattern from a specified change in fit attribute.

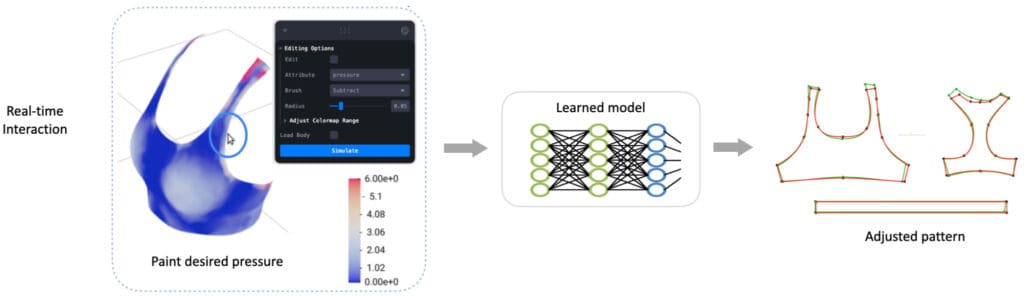

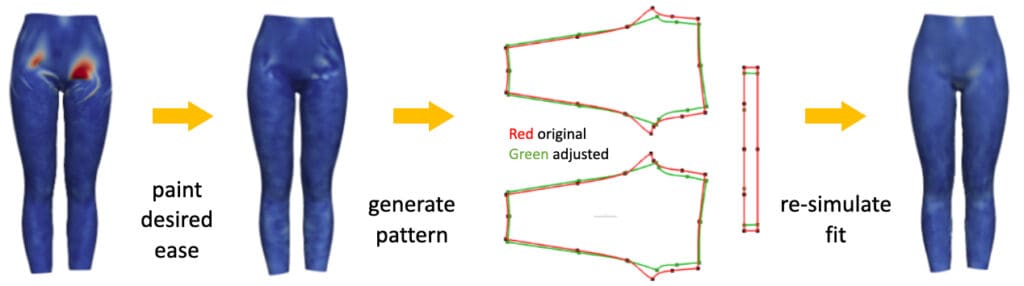

In the interaction phase, the pattern maker is presented with a 3D garment with the fit attribute (e.g., pressure or ease) displayed on the garment. To demonstrate the interaction, we developed a simple painting interface with which the pattern maker can increase or decrease the attribute on the body using highly intuitive “painting” gestures. Within seconds the model predicts the pattern changes and displays it to the user.

We have successfully experimented with different types of garments, including a sports bra, a tank top, and a pair of leggings, and two fit attributes that are related to comfort: ease and pressure. Here’s another example with leggings:

Our method introduces an intuitive way to directly express fit adjustment goals and is easier to use. We believe this use of AI and 3D can save time, improve fit quality, and improve the productivity of this critical phase of product creation.

Our system demonstrates how recent advances in generative AI can be fruitfully employed to make clothes that fit well and reduce waste. Using accurate and scalable virtual fit tests, the uFit system empowers pattern makers and, potentially, anyone to make intuitive changes to the fit, by “painting” the desired fit attribute directly on the garment.

“Thank you for this timely competition on how AI may transform the apparel industry! We believe the blend of 3D, accurate physics, and deep learning will have a major impact on product creation. We are grateful for this opportunity to present our research to the community”

– Megha Shastry

Apotheosis Group: Apparel FIT Avatar System via Accurate Replica Humanoids - A Use Case for Apparel Avatars

Team Member: Kathy Schildmeyer

New technologies, evolving design tools, and shifts in shopping environments are driving systemic changes in the Fashion Industry. Regulatory pressures to reduce greenhouse gas emissions in supply chains further complicate the landscape. Apotheosis Group addresses these challenges by introducing a proprietary humanoid avatar that ensures accuracy in design, waste reduction, regulatory compliance, and shopping precision. Apotheosis Avatars will provide methods and solutions which if implemented properly will directly reduce waste, bring regulation compliance, and enhanced shopping experiences. The APOTHEOSIS avatar impacts the apparel design cycle in the following ways.

Waste Reduction

McKinsey research highlights that 80% of waste is related to the product development phase of the design cycle. While current models focus on waste in manufacturing and consumer relations, the creative process has been overlooked. How a style is designed should be a traceable metric. All style creation starts as an idea. How that idea gets designed is where the waste starts. Designers are taught to design over a template or croque which is scaled to an unrealistic height and size. The target customer is most often 6 sizes larger and 18 inches shorter than the base template. Apotheosis understands this first stage of waste. The confusion begins with art ideals and not reality human considerations.

Having tested multiple avatars used for apparel design we have identified the shortcomings and functional flaws that interfere with realistic aesthetic 3D style creation. The creators and suppliers of 90% of the current avatars lack understanding of how fit functions in reality, relying on gaming rig systems for easy work. These avatars do not match to human body structure or function, this dilutes the fit data found in the original human body capture. Apotheosis Avatars are designed for real apparel manufacturing, reducing sample integrations by up to 70%, addressing the systemic issues in this critical phase of the design cycle.

Regulatory Satisfaction

Apotheosis Group acknowledges that the majority of 3D design users lack expertise in fit evaluation. To bridge this gap, the company offers a tested humanoid solution, ensuring that size and fit ranges are validated in reality before release. Understanding the industry’s reliance on field-tested solutions, Apotheosis Group aims to equip future designers with tools for assessing fit aspects. Apotheosis Group emphasizes the importance of using tailoring and renewable textiles, providing data easily integrated into digital passports for sustainable product creation. Notably, our metrics reveal substantial waste reduction in poorly fitting items, such as up to 4 added inches of cut waste per unit for men’s shirts and about 5 inches for women’s tops, dresses, or pants.

Shopping Accuracy

Existing virtual try-on technologies often lack a thorough understanding of fit, relying on simplistic approaches. Apotheosis Group, through its sister company Authentic Fit Technology (AFT), introduces patented fit systems for creating 3D models that consider the real aspect of fit in relation to the body. This approach extends to virtual shopping experiences using smart mirrors, holograms, and VR sets, ensuring accurate representation and interaction with consumers. Consumers can see the body shapes that were used to design the products and see how this meets their fit needs. For example, a man with a sway back will need a different jacket than one designed for the portly shape. By embedding fit education into the digital experience, Apotheosis Group aims to guide users in navigating the evolving landscape of virtual shopping. Our sister company AFT works with pattern data and user data to define the preferences for the esthetic preference and styling, while delivering brands the mathematical success of their fit swim lanes. This patented approach allows the brands to be more agile when making designs and patterns that users can be comfortable wearing and love over a long time.

In summary, Apotheosis Group emerges as a solution to the fashion industry’s challenges by providing a humanoid avatar that addresses waste reduction, regulatory compliance, and shopping accuracy. Through a focus on real-world fit, sustainability, and innovative technologies, Apotheosis Group aims to harmonize the industry with the demands of a changing landscape, ensuring a seamless and accurate commerce experience.

“The validation from the IEEE & 3DRC delivered a much needed confirmation of our tools, and systems we want to bring to an industry. This support brings an ethical and integrity based support system to our field. Our Gratitude for everyone involved in the review process has been infinite. We feel like this is very much a team effort that has helped our group take leaps forward in our mission.”

– Katy Schildmeyer

About 3D Virtualization for Retailers and Brands at IEEE SA

The 3DRC Grand Challenge is a joint initiative of the 3D Retail Coalition (3DRC), IEEE SA, and Kalypso for the retail/apparel industry to explore technology applications and standards enabling next-generation consumer experiences. The project originated with support from the IEEE 3D Body Processing (3DBP) Industry Connections (IC) activity, a collaborative effort to assess standards opportunities intersecting emerging technologies to enhance industries such as retail, medical, health and wellness, and sports and athletics. Participation in 3DBP subgroups and activities is welcomed.

Learn more about the 3DRC Grand Challenge and the 3D Body Processing IC Activity.